During our personal tour of the OceanView Mine in January 2011, we purchased a few segments of Pink Tourmaline from the Stewart Lithia Mine, 2 Triphane (Yellow Spodumene) Crystals from the Pala Chief Mine, 1 Kunzite (Pink/Purple Spodumene) Crystal from the OceanView Mine and one INCREDIBLY beautiful large Kunzite Crystal that showed a wonderful blue purple down the long axis, a teal green ninety degrees to the long axis, and a purple or bluish down the other axis. Both these Kunzites were doubly terminated and were found in the vicinity of the famous Big Kahuna Pocket in late 2010.

Read about the adventure into two important mines that produce Spodumene/Kunzite, in January 2012 by the owner of All That Glitters via personal invite by the marketing agent and owner of these mines: Oceanview and Pala Chief Mine - January 2012

The faceting discussed below, is from the large Kunzite crystal described above - which weighed 154 grams (770 carats). Since this was a beautiful and unique specimen, we did offer this initially for sale, and noted that we were considering faceting gemstones from the crystal. After warning of the potential cutting of this piece to those who might have an interest in this unusual crystal, we sent it to our Award Winning Certified Supreme Master Gemcutter, Stephen Kotlowski G.G., CSMG, to study and contemplate its cutting. (This is indeed a long title, but it is accurate. "Award Winning" as he has won many awards including AGTA's Cutting Edge Competition and he holds a Certificate from the American Society of Gemcutters with a rank of "Supreme Master Gemcutter"!)

An email from Stephen confirmed what we had first thought when we first saw the crystal - "that thing is amazing! clearly several stones from that crystal and oriented down the axis will be the way to go but will wait and see after I figure what needs to be removed and mark out the saw cuts etc. or I can just place it next the other crystals in my collection...."

The photos below take the viewer through the cutting of the first large faceted Kunzite from this crystal.

|

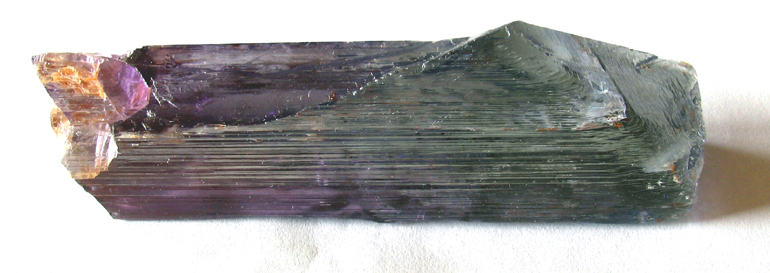

| Recent gemstone rough finds in San Diego Co. included the new

Spodumenes from theOceanview Mine.

During the 2010 mining of the Oceanview Mine, the 'Big Kahuna' Zone was discovered. This was a

large pocket with a series of smaller satellite pockets. The zone yield

Spodumenes, Quartz, Tourmalines and Beryl. This is one of those crystals

discovered in the vicinity of the Big Kahuna Zone, weighing in at

770cts (154 grams). We estimate

this piece to measure approximately 4-1/2 inches long. NOTE the color variation from the

deep bluish purple on the

left and eventually becoming a green or teal on the other end.

This photo was taken in the office of All That Glitters when this crystal

was initially displayed to the public for sale. Our Award Winning Supreme

Master cutter took the other photos below after he received the crystal for

study and potential faceting. |

|

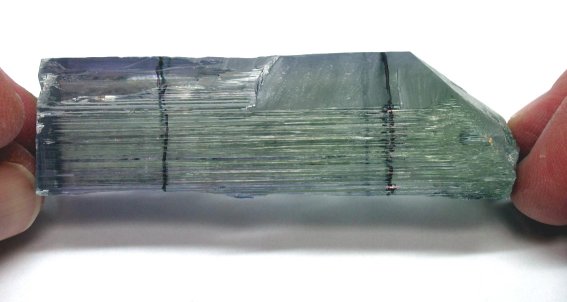

| As one can see in this shot the crystal is turned slightly about 45 degrees and the greenish axis can no longer be seen. |

|

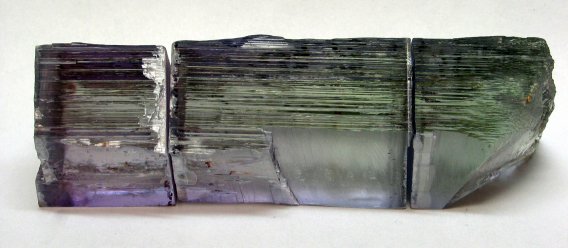

| Just a slightly different angle can cause the color of this crystal to

change as the axes being viewed changes. In this photo, you can see a

bluish component. When looking down the C axis (the long axis), the color

was so deep a flashlight was necessary to see the color. It was a very deep

bluish purple. Rotating it slightly produced a bluish color, and rotating

more produced a green. The crystal also changed color down the axis to the

green shown in the other photos. Stephen has sliced off the left hand end

which had some issues. There is a smaller gemstone to be had here, after

careful trimming and orientation. There is an actual clear etched section

on top of the crystal that is already sawn off but in place to show its

original location. |

|

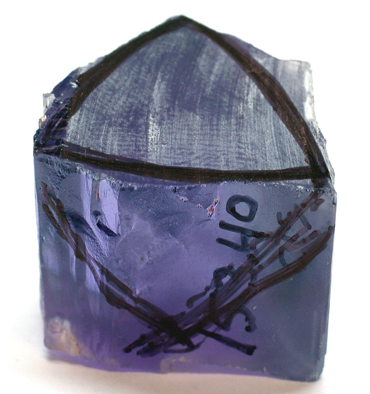

| The clear etched piece was not as readily removed as one had hoped and

actually had to be sawn off. At this point, the small colored segment

removed from the base weighs approximately 83cts, the clear etched piece on

the top weighs 38.50cts and the remaining large crystal weighs 602cts. The

clear piece is interesting due to the natural etching and is in the

possession of our supreme master cutter. Stephen weighed the crystal on his

scale prior to any work and it weighed 769.80cts. The total of the 3 pieces

is now 723.65cts. Weight loss due to flaking, chipping and 2 saw cuts

totals about 46cts - which would be equivalent in weight to a nice sized

Kunzite when faceted! |

|

| Four emstones can be faceted from this piece. Stephen has marked off both

ends, to produce two gemstones. The middle section is not marked off

presently, but this will also produce 2 more gemstones. There is a 5th

gemstone that will be much smaller, and that is from the original first cut

of the crystal, far left hand side and can be seen in previous

photos. |

|

| Same step in the process as described above, but the crystal was

rotated and one can now see the predominate green color in this

view/direction. |

|

| The trim saw blade is almost through the crystal in the first of two

cuts being made. |

|

| The first piece that will be faceted has now been removed from the main

part of the crystal. |

|

| The other termination of the crystal, the green section, has been

removed. The 'middle' section shown here on the right contains both a

purplish color and a greenish color and will need to be split in the future

creating two more facet grade pieces. |

|

| This crystal was unique for a number of reasons - two of those reasons

is seen here. 1.) The crystal fades from a bluish purple to a green 2.) Though the crystal was etched and had the expected striations of a Spodumene crystal, there was a very smooth almost polished looking surface on one of the sides, which was natural. Here, you are looking at that smooth natural surface with the weights of each piece that was just trimmed. |

|

| Similar to the above photo but the crystal has been rotated about 90

degrees from the position above. You can clearly see more green in this

direction. |

|

| Again, the crystal has been rotated another 90 degrees. You can see the color shading from purplish to green, and the natural striations are very present. The three segments weigh a total of 593.15cts approximately. With these two trim saw cuts, there was an associated weight loss of approximately 9cts. |

|

| Looking down the C axis, down the length of the crystal. The view that

you see will become the tables of these future gemstones. |

|

| Looking down the C axis again, but from the opposite direction. If one were to rotate the segment on the right hand side, one would see the green color observed in some of the photos above! |

|

| This is the left most segment one sees in the above photo. It is the left most segment of the main crystal after the first smaller segment was trimmed from the left side of the crystal and placed aside for future cutting. Cutter has roughly sketched the shape of the future gemstone - a trilliant. |

|

| Both a top and side view of the piece selected for faceting. Cutter has

sketched the pavilion (bottom) on to the side of the rough. Note that the

rough weighs 153.40cts. Most people do not realize that a properly faceted

gemstone will typically yield ONLY 20% of the original weight. That means

that 568px of the rough is lost to cutting as it is ground away. We are

expecting perhaps a slightly larger yield because the shape of the rough is

roughly a trilliant. If we do indeed get a 20% yield, we would expect about

a 31ct gemstone. |

|

| The bottom has been finished at 500 diamond grit and the girdle was

done with 180 diamond grit at this point. Every facet must go through the

same sequence of various diamond grits, starting from coarsest grit and

going to the finest. In the case of faceting this Kunzite, the laps used

consisted of 180, 500, 8000 (pre-polish) and 200,000 diamond grit (final

polish). |

|

| A shot looking down on the bottom and culet/point of the gemstone - the

fine 500 grit cutting lap was used after the 180 grit lap to smooth this

side before the girdle/side facets were cut in with 180 coarse diamond as

shown in the previous photo. |

|

| The 500 grit diamond lap was used to finish the girdle side and then

the pavilion girdle brake row was cut in with this lap giving the stone the

same fine finish over all of the facets just before moving on to 8k diamond

pre-polish. |

|

| Here we see Stephen has pre-polished the entire bottom of the stone

with 8k diamond and also added the last six main facets, two of which can

be seen off the corner and look like elongated kite shapes in this

photo. |

|

| The bottom has been completed and will not be touched again unless

problems arise, and that is very possible when working with Spodumene. The

final polish is 200k diamond. |

|

| The gemstone has been transferred to a different dop so that the

crown/table can be faceted. |

|

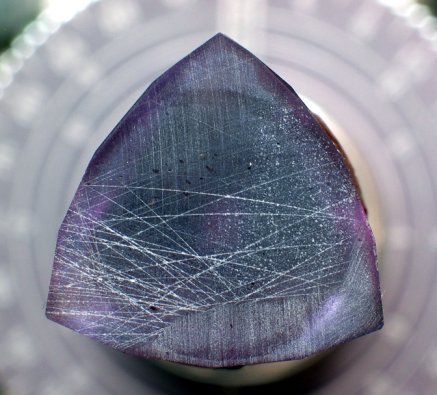

| Looking down on what will become the table and crown. One can see

scratches from previous diamond grits used to create a flat surface where

the dop was attached when starting to work on the bottom. These scratches

will be removed during the next steps. |

|

| Fraying at facet junctions due to cleavage. This issue was encountered

at two of the three corners. |

|

| Issue encountered above is seen on another corner. |

|

| Issue/problem continues as the crown is continued. |

|

| Continuing to work on the above issue. An extra facet is added at the corner which resolves the problem at this point. This new facet will be added to each corner for symmetry. This interesting predicament and the addition of the extra facet at the corners, allows the gemstone to be set more easily, securely and potentially avoids future cleavage issues. Stephen Kís experience spans 45 years, is an expert at working on the fly as they say, and has experience with such issues when they arise. (He rarely even works off of existing cutting diagrams and makes up custom designs in the cutting pattern as he goes or is necessary when unexpected problems arise!) |

|

| Third corner has no issues and it is not in a cleavage plane. Though no problems on this corner, that extra facet noted above must now be cut into this corner! |

|

| View of the table and crown. The new corners have been cut in to remove

the fraying that was previously encountered. Note the color change of the

gemstone for a few reasons - you are looking down another axis now, there

is red dopping wax on the bottom and one can no longer see through the

gemstone. |

|

| The beginning of a new cutting sequence, all of which are being cut in with the fine 500 grit diamond lap. One sees facets take shape only to be removed to some extent in the next step, leaving behind differently shaped facets that begin to take the form of the finished facets. |

|

| Further along on the crown and the diamond grit has gotten finer, you can see that added facet that is currently in the shape of a teardrop. |

|

| Stephen has taken the time to rub each of the facet junctions with an

aluminum rod, which allows one to see the current facet arrangement. (This

is not something that is done in faceting, and was only performed to show

the viewer the facet arrangement at this point) |

|

| Similar view to the above. Gemstone has been rotated about 45 degrees

from the position above. A veil can be seen in the gemstone at this point,

but will be hidden by brilliance when completed and shouldn't detract from

the finished gemstone when completed. |

|

| Continuing with even finer 8,000 diamond grit obtaining a perfect

pre-polish by removing all issues and creating a near mirror-like surface

on each facet just before the final polish of 200k diamond. Table has been

completed and finished with an amazing fine 200k diamond grit! Many cutters

may follow up with a final polish of 50k diamond, but Stephen has been

using 100k which we felt provided a superior finish/polish compared to most

other cutters. With the 200k diamond, it doesn't get ANY better! |

|

| 41.80ct Modified Trilliant Kunzite from the Oceanview

Mine, Big Kahuna Pocket vicinity - San Diego County, California,

USA (Photographed under 65K Natural Daylight/Full Spectrum Lumichrome light) |

| Final Comments: Every facet you see in this finished gemstone requires each facet to be worked on with a different grit, going from very coarse grit to the very finest which gives it the final mirror-like polish. In this case, each facet had 4 different diamond grits: 180, 500, 8000 and 200,000. Some facets might take longer than anticipated, as is the case with a number of facets on this particular gemstone (a frequent occurrence for those gems/minerals that have cleavage, Diamond included). The cutter did indicate that he had worked 45 minutes on a particular facet, so one gets an idea of the expertise, precision as well as patience that is required. For a gemstone of 100 facets, one could polish 400 facets by the time it is completed. This also assumes no problems or issues arise during this long process, and as the story above indicates, some issues were encountered, with extra facets being added. Note that one can never really tell what the color of the gemstone will be when it is still on the dop. One must remove the gem from the dop and remove all wax before the true color and optical properties of the gemstone can be determined. (Compare the finished gemstone here with the photo directly above still showing the gem on the dop) (omvl-12-03a) $200/ct |

| Thanks go

out to our Award WInning Supreme Master Gemcutter, Stephen Kotlowski, G.G.,

CSMG, for the photos provided during the steps above, his expertise in

faceting and communication. |

|

|

| Photographed under 65K Natural Daylight/Full Spectrum Lumichrome light.

One can see more purple with blue highlights. Under diffused home lighting

(natural) as well as by a window (indirect sunlight), the body color is

more purple with blue highlights. |

This Kunzite tends to be more pink under office fluorescent lights and

incandescent lights. It all depends on what wavelengths are available in

the light source. |

The above gemstone may be available to purchase. To View Kunzites that All

That Glitters may have in stock,

Visit our Kunzite Page: Kunzite Photos

Page

The above steps show a successful gemstone being faceted, but there is no guarantee of success. In fact, the very next piece of rough from the crystal above to be placed into the faceting process, cleaved and exploded. Faceting frequently does not go exactly as planned, and that is very often the case when faceting gemstones from the rough. So many issues can arise that make the gemstone smaller, or one finds inclusions that one didn't see prior to purchasing the rough; the gemstone can be overly dark and though saleable for most businesses, this wouldn't be a gemstone for All That Glitters. Also, there are times, and sometimes more frequently than desired, things go terribly wrong. This can happen with Tourmaline whose crystals are frequently under stress, and they will crack or break. With Spodumene (Kunzite and other varieties) and DIaspore, issues are more the norm. It would be uncommon NOT to have something that must be tweaked, modified, etc. In the case of faceting the second piece of the crystal above, the very tip/termination which was green, teal and purple, a catastrophe occurred. The photos say it all - see below. A wonderful 161ct piece of rough, which should have yielded a 32ct (at minimum!) or so gem, may be an entire loss. The first gemstone was faceted successfully. This second one could be an entire loss, with estimates of at least $6000 or more from what we expected to yield in the end. What will the other 3 pieces produce? Will they produce??

The public and trade rarely hears of the risk that one takes when faceting gemstones (or even refaceting). When it comes to Spodumene and Diaspore, even the experts cannot insure what will happen when trimming, sawing and faceting begins. This is frequently taken into consideration in pricing these gemstones.

|

|

| Side View - Crystal

Termination |

Top View - Crystal

Termination |

|

|

| Broken rough/crystal in first steps of

faceting |

|

We did manage to save the largest section seen in the above photo to facet a 16.01ct gemstone. This represents a yield of only 10% as the original piece of rough was just over 160cts, making this a loss of 144cts. (Rule of thumb is typically a 20% yield from rough and that can be lower due to issues or higher if the shape of the rough is similar to the cutting design - it can be considered a big gamble faceting a gemstone from the rough.) See the finished gemstone below.

| 16.01ct Bluish Lavender California Kunzite, Oceanview Mine, Big Kahuna Zone approx late 2010 (2nd gemstone from an unique bi-color crystal!) | |

|

|

| Photographed under 65K Natural Daylight/Full Spectrum Lumichrome light | Office fluorescent/incandescent - takes on a more pink color and one could call the color Pink Ice. It has incredible sparkle and brilliance! |

| A 16.01ct Natural Kunzite from the Oceanview Mine in California, faceted by our Award Winning Supreme Master Gemcutter. The color is light bluish lavender to a pink ice color depending on what wavelengths are available. The cutting style is a one of a kind creation, with a portuguese bottom and modified double barion top, measuring approximately 13.78 x 12.49 x 11.65mm. (UK-Portuguese Barion rectangle) (ovml-12-03b) (This was an INCREDIBLE SPARKLER as well as all the other pieces that our Supreme Master Gem Cutter faceted from this crystal; this now resides with one of our long time customers in the United Kingdom.) | |

Visit our Kunzite Photos Page to view available inventory: Kunzite Photos Page